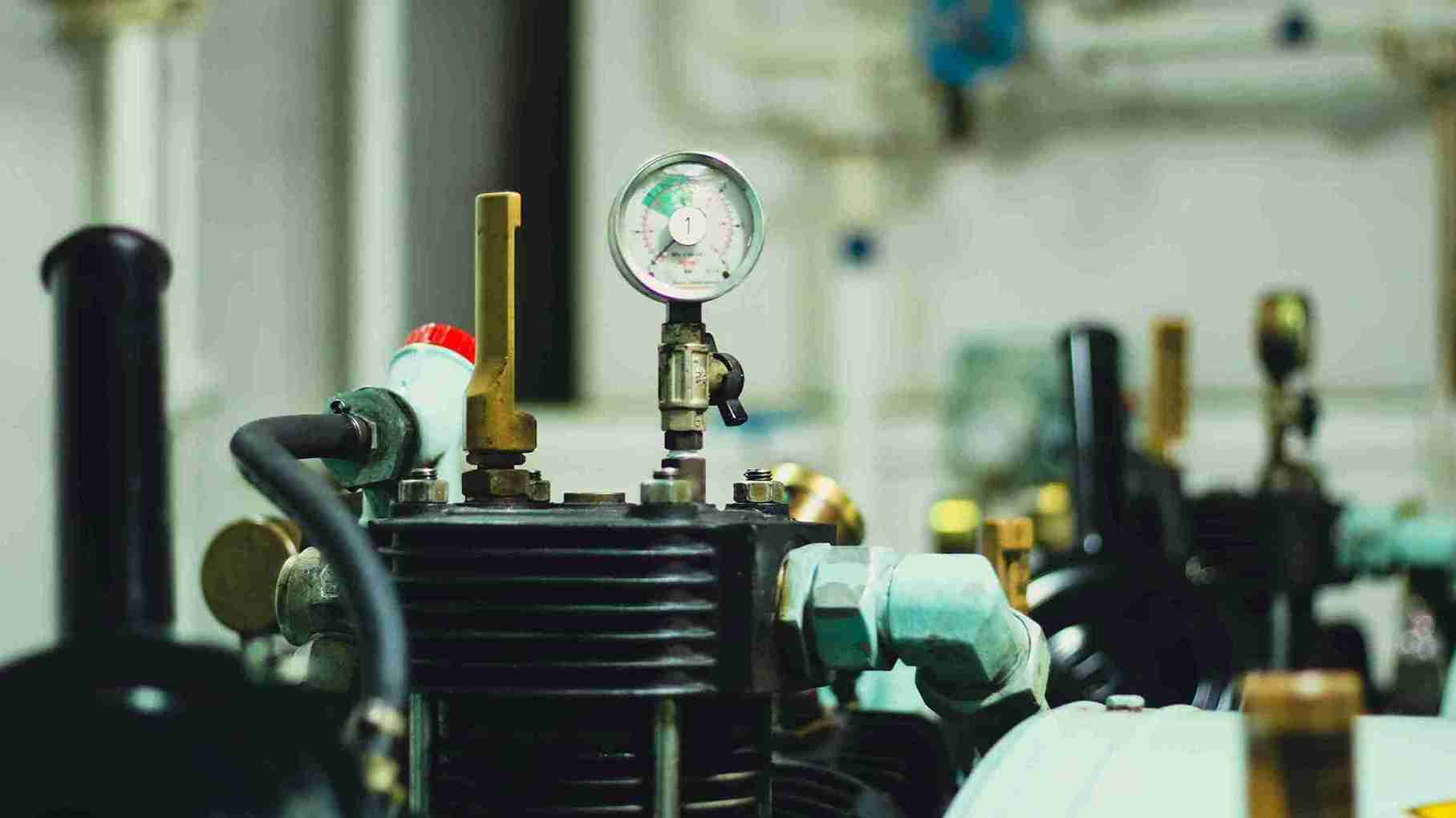

An “air compressor” is a clever contraption that transforms power, typically sourced from an electric motor, gasoline engine, or diesel engine, into the mighty potential energy locked within pressurized air. This compressed air is a versatile resource that finds its purpose in a multitude of applications spanning across diverse industries.

Functions of Air Compressor

To convert power into compressed air for different uses, an air compressor goes through a series of important steps. Let’s break down its functionality:

Taking In Air

It all starts with the intake of air from the atmosphere. Air compressors pull in ambient air and use filters to get rid of impurities and contaminants.

Pressurizing

Next, the intake air is compressed to a higher pressure. The method of compression varies depending on the type of compressor being used. For example

1. Reciprocating (Piston) Compressor

They utilize a piston-cylinder setup to compress air.

2. Rotary Screw Compressor

These compressors make use of rotating screws to compress air.

3. Centrifugal Compressor

They employ a rotating impeller to accelerate and compress air.

Heat Generation

During the compression process, heat is generated. Certain compressors are equipped with cooling systems to handle this heat and ensure that the air does not reach extremely high temperatures.

Tank Storage

Compressed air is stored in a tank or receiver, serving as a buffer. This tank enables a steady and regulated release of compressed air, even when the demand varies.

Pressure Control

Pressure regulators are commonly found in air compressors to regulate and maintain the desired output pressure. This guarantees that the compressed air fulfills the specific needs of various applications.

Distribution and Utilization

Compressed air is then distributed through pipelines or hoses to different points of utilization. It empowers a vast array of tools and equipment, including pneumatic tools, machinery, and systems in industries such as manufacturing, construction, and automotive.

Automatic Shutdown

Numerous air compressors are equipped with automatic shutdown systems. Once the predetermined pressure level is achieved in the storage tank, the compressor ceases operation to prevent over-pressurization.

Release and Reuse

As compressed air is utilized, the pressure in the tank decreases. The compressor cycles back on to maintain the preset pressure. This cycling continues as necessary, ensuring a continuous supply of compressed air.

Applications of Air Compressor

Air compressors are widely used in different industries and settings because of their versatility and capability to deliver a reliable and strong supply of compressed air. They have numerous applications, some of which include:

1.Pneumatic Tools

Nail guns!

Ideal for construction projects, nail guns provide a speedy and effective way to fasten nails.

Impact Wrenches

Perfect for automotive repair and construction tasks, impact wrenches make fastening and unfastening bolts and nuts a breeze.

Paint Sprayers

In the automotive and construction industries, paint sprayers are the go-to for achieving a smooth and efficient application of paint.

2.Manufacturing and Industrial Process

Pneumatic Machinery

In manufacturing processes, compressed air is the driving force behind machinery and equipment.

Control Systems

Industrial automation relies on control systems to operate valves, actuators, and other control devices.

Material Handling

Conveyor systems and lifting equipment are powered by air compressors, making material handling a breeze.

3.Construction and Demolition

Jackhammers

Compressed air is utilized to operate jackhammers, enabling them to break through concrete and rock.

Pneumatic Drills

These drills are commonly used in construction and mining for drilling and boring tasks.

4.Automotive and Repairs

Tire Inflation

Air compressors play a crucial role in inflating and ensuring the correct tire pressure for vehicles.

Air Tools

Automotive workshops rely on air tools, including impact wrenches, sanders, and grinders, which are powered by compressed air.

5.Food and Beverage Industry

Packaging

Compressed air is used for packaging processes such as sealing and labeling.

Beverage Dispensing

In some cases, air compressors are used in dispensing systems.

Conclusion

Compressed air systems play a crucial role in various industries as they provide power to tools, machinery, and control systems. Their importance stems from their adaptability and effectiveness, which are essential for the progress of industrial processes and continuous technological development.